ALL TIME Vertical Welders Features

- Adopts EGW (Electro Gas Welding) process for high speed carbon steel vertical welding with FCAW (Flux Cored Arc Welding) Process option for alloy steel vertical welding

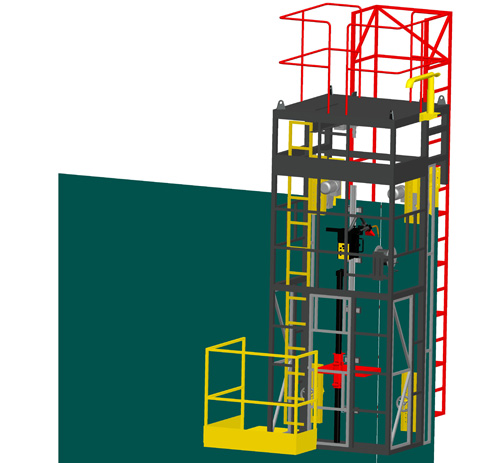

- Lightweight travel carriage, self-propelled, weatherproof, fully contained operators cabin which allows safe access to the weld joint and easy set up and install

- Lightweight Aluminum track, quick mount electro magnets , easy assembly and disassembly;

- Real time monitoring of arc and automatic control of weld pool level, welding gun position and automatic adjustment of electrical stick out;

- Sequence control in “Auto mode” to allow one button startup.

- Onboard- self-contained continuous water cooling system

- Fully integrated with LINCOLN electric welding systems as standard (other welding systems on client’s request)

- SEW drive system for reliable and steady travel

- Different standard configurations for site erected Bottom Up and Top Down erected storage tanks or heavy wall cylindrical structures (eg. towers, blast furnace).